When it comes to woodworking, nothing is more essential than stability and precision. Whether you’re gluing edges, assembling furniture, or holding pieces during sanding or cutting, clamps are irreplaceable tools that ensure your work stays in perfect alignment.

A good clamp prevents movement and slippage, making the difference between a professional finish and a sloppy job. For both amateurs and seasoned craftsmen, selecting the appropriate woodworking clamp can improve efficiency and accuracy, ultimately elevating the quality of your projects.

The Foundational Role of Clamps for Woodworking

source: hammerroo.com.au

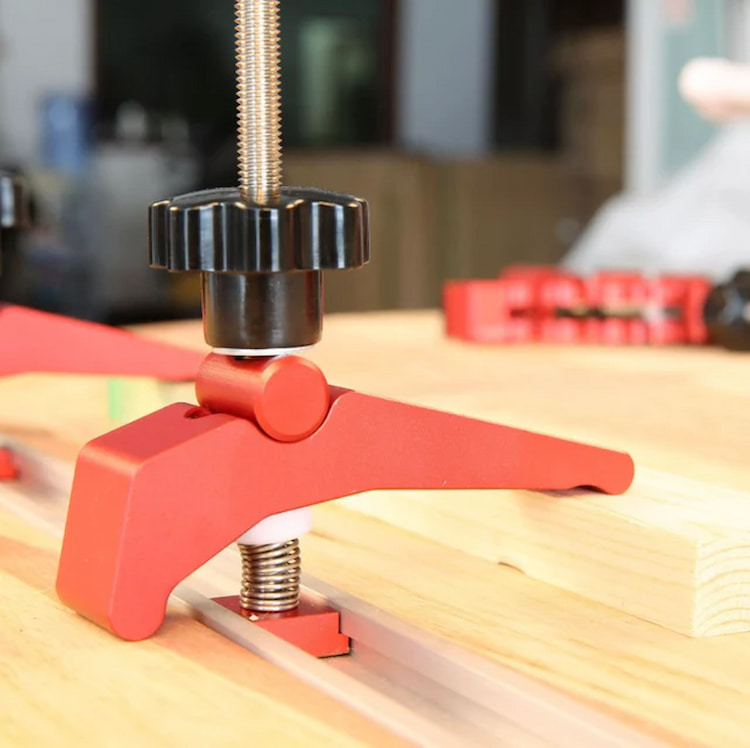

A woodworking clamp’s primary role is to hold wood pieces securely together during various stages of a project. These tools help apply even pressure across surfaces, which is especially important when bonding wood with glue. They also provide stability during sawing, drilling, or assembly, allowing for safe and precise work. When glue is involved, they ensure the joints are tight, with the glue penetrating evenly into the fibres, creating a strong and durable bond.

Without them, the risk of misaligned joints or weak adhesives significantly increases, which can compromise the entire project. That said, the versatile woodworking clamp is a staple in every workshop, serving multiple functions that range from simple holding to complex joint assembly.

Options for Every Need and Tips for Choosing Clamps

Woodworking clamps come in various styles designed for different tasks and projects. Some of the most popular ones include:

- F-clamps – versatile and widely used for general tasks;

- Bar clamps – provide strong pressure across larger surfaces;

- Pipe clamps – flexibility for long or irregular shapes;

- Corner clamps – ensure tight joints in frames or boxes.

When choosing, consider the size and weight of the workpieces. Smaller ones are suitable for detailed or delicate projects, whereas larger, heavy-duty ones are better for big panels or furniture assembly. It’s also important to select options with padded or protective jaws to prevent damage to the wood.

When it comes to materials, steel or reinforced plastic are the gold standard of durability, able to withstand the rigours of repeated use. Adjustability and ease of handling are additional factors; quick-release models, for example, simplify positioning and removal, saving time.

Purchasing a woodworking clamp that matches your project’s scope and your comfort level will serve you well over time, leading to tighter joints and more professional results.

What Makes a Clamp Last

The longevity and performance of a wood clamp depend significantly on its construction materials.

- Steel clamps are robust and handle high pressure, making them ideal for heavy-duty tasks.

- Aluminum clamps are lighter but still durable, suitable for lighter projects or extended use where weight might be a concern.

- Modern plastic options, reinforced with steel components, provide corrosion resistance and ease of handling, although they may lack some of the maximum gripping power of metal.

The quality of the moving parts, like threaded screws or ratchets, is crucial for smooth operation over time. Clamps with precision-machined threads and well-fitted jaws resist wear and maintain consistent clamping force.

Well-made clamps are less likely to slip or break under pressure, protecting your work and allowing for precise, repeatable results. Investing in durable materials and construction means your clamps will serve you reliably for years, making them worth the initial expense.

Safety and Maintenance Tips

Correct use and maintenance enhance safety and prolong lifespan. Here are some tips:

- Apply only the necessary pressure. Over-tightening can cause wood to crack or deform.

- Regularly inspect for signs of wear, such as stripped threads, bent frames, or damaged jaws, and replace any faulty components promptly to avoid accidents.

- Clean after each use to prevent rust and keep moving parts functioning smoothly.

- Lubricate threaded screws and ratchets to maintain ease of operation and reduce the risk of seizing.

- Always use clamps evenly. Placing multiple clamps around a glued joint distributes pressure uniformly, preventing bowing or weak spots.

- When working with sensitive or expensive materials, opt for options with padded jaws to prevent surface damage.

Adopting good maintenance practices ensures your clamps remain safe and effective, making your woodworking more enjoyable and less risky.

Building Confidence in Your Workshop

Having the right wood clamps readily available in your workshop transforms your workflow from tentative to confident. Whether engaging in small repairs or constructing intricate furniture, dependable clamps provide the stability you need. Being familiar with the different types and their best applications saves time and prevents frustration. Proper selection and maintenance not only result in better craftsmanship but also deliver an element of professionalism that elevates every project.

From simple gluing tasks to complex assembly, the right clamp ensures your work is safe, precise, and durable. These tools are an essential part of a skilled woodworker’s arsenal, and understanding their features empowers you to make smarter decisions, resulting in superior projects and greater satisfaction.